Is MDF Really That Bad? A Carpenter’s Honest Answer

MDF: A Primer

So, is MDF any good?

Short answer: not really.

Long answer: in some situations, it makes sense.

Medium Density Fiberboard is an engineered wood product that’s basically made from sawdust and resin. The elements are smashed together under heat and pressure to create MDF sheet goods. There are also other “wood” products made with this technique, trims, moldings, and other decorative “wood” materials.

Because of the way MDF is made, it’s heavy as hell. Carrying a ¾” sheet will dislocate your elbow and leave you injured before your budget project even begins. So bring a friend or ask for help before the ego takes the driver’s seat. MDF comes in a few common sizes at the local big-box store: ¾”, ⅝”, and ½” (sometimes ¼”). The most useful size is ¾”. Most sheets come in 4’x8’ dimensions.

Possible MDF Use Cases:

The advantage of using MDF has improved a bit over the years, especially considering how expensive “the good stuff” (real wood and plywood) has become. Still, I rarely recommend MDF unless you’re covering it with something, veneer, laminate, fabric, or paint.

I don’t care what the guy at the counter told you: MDF is not structural. It’s best for decorative purposes only. A lot of people use it for shelving, sadly, that also includes me. I’ve built and installed a nice little shelving unit in my kids’ bedroom closet, some kitchen cabinet doors and trim, and yes, I trimmed the entire interior of a house with it. Forgive me Father, for I have sinned.

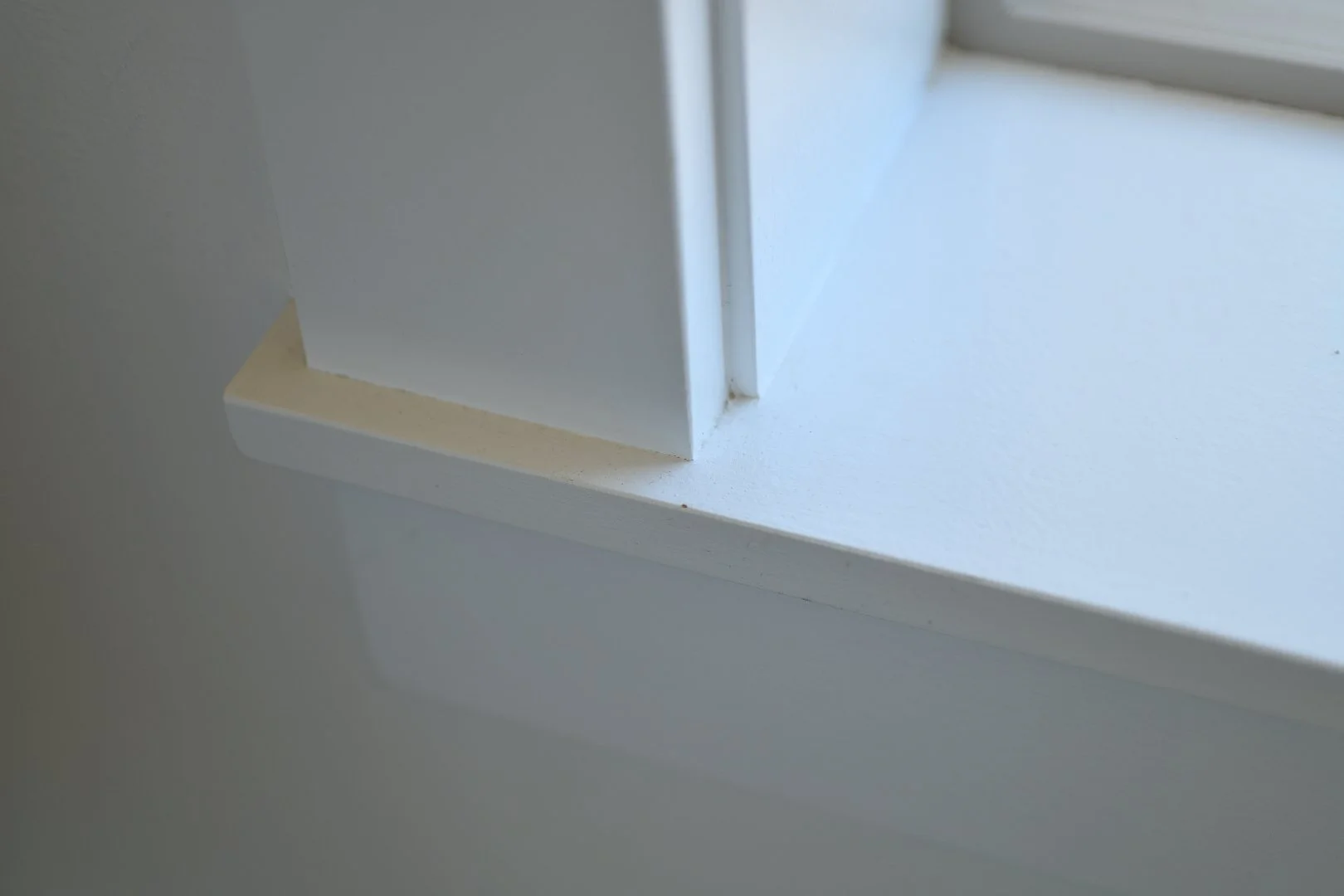

Window casing is 100% MDF

As shelving, MDF does alright. It only needs to sit there and hold stuff. But it’s important to either sandwich two sheets together (making it 1½” thick) or support it every 24” to 30”. Some people go 36” or 48” and pay the ultimate price later: the dreaded MDF sag.

If you’re building bookshelf-style closet storage, use as many dados as possible. Mechanical joints like that will outlast everything else.

Trim and Baseboards

Hinge bore into MDF

MDF can be a good option for casing and baseboard. If you’ve got a table saw or track saw with a decent blade, you can rip a 4x8 sheet down to whatever width you need.

A 1x4x7 MDF door casing costs about nine bucks. If you rip your own from a sheet, it drops to roughly three. And it’ll look better too, true ¾” thick, without those over-rounded edges you get from pre-made trim.

Cabinet Doors

As cabinet doors, MDF does surprisingly well because it’s relatively stable. Your doors won’t warp over time unless there’s pressure on them.

If you use MDF for cabinet doors, go with concealed hinges, the kind that sit in a circular mortise inside the door. That mechanical fit will hold longer. Don’t screw butt hinges into the face or edge of MDF. They’ll hold for about seventeen minutes before the screws start working loose.

When painting, seal and sand the edges. The faces take paint well, but the edges don’t. You can also make fridge panels and decorative trim pieces with MDF — just keep it non-structural.

Vanity panel attached to upper cabinet

Pro tip: Paint every surface; back, front, top, bottom, sides. Moisture is MDF’s natural predator. Painting all sides drastically reduces the chances of failure from humidity or spills.

Cutting MDF

The best way to cut MDF is with a sharp, high-tooth-count blade, just not your best one. The resins and binders in MDF will dull it fast. A 40-tooth blade works well for general cuts.

Because MDF is heavy, it often makes sense to cut it into manageable chunks before working it further. The same goes for router bits: use sharp ones. Dull bits will leave fuzzy edges on your dados and rabbets. Higher RPMs on your router help too.

Cut outside. Away from open windows, cars, or anything you don’t want covered in dust. MDF dust is super fine, what I like to call forever dust. It hangs in the air forever and finds every open orifice available. So wear goggles, use a HEPA vac if you’ve got one, and buy the best dust mask you can afford.

Fastening MDF

There are only three “good” ways, and I use that word loosely, to fasten MDF: pocket screws, through screws, and adhesives.

Pocket screws work for light-duty shelves or carcasses, but double the number you’d normally use and add Type 1 Titebond wood glue for extra hold. The downside is the giant holes they leave behind.

Tips:

High drill RPM for clean pocket holes.

Low RPM when driving screws, the core is soft.

Clamp your work if possible.

Through screws are for attaching cleats or sandwiching MDF to itself or other materials. Always pre-drill the piece you’re attaching so the screw can move freely and pull tight. Use Type 1 Titebond if it’s permanent. Only screw into the face, never the edges, they won’t hold.

Since fasteners aren’t great, adhesives are actually a solid option. Modern glues like Loctite PL Premium hold well, but you’ll need clamps or something to keep things in place while it cures.

You can pin things with a brad nailer, but it adds extra sanding and hole-filling, and the nails don’t hold much anyway. Whenever possible, rely on dados and rabbets, those joints will last.

Finishing MDF

Finish MDF with primer, then two coats of paint. Most primers are water-based, so sanding after priming is a must, the water raises the fibers and makes it rough.

Lightly sand with 180–220 grit and vacuum up the dust. Try not to sand through the primer or you’ll have to reprime.

Sliding door casing

Edges always need extra attention. They’re more porous than the face, so they’ll drink up primer unevenly. Sand smooth after priming and again after your first coat of paint. Don’t skip that step, the difference shows.

Bottom Line

MDF has its place in the building trades, if it didn’t, they wouldn’t keep it in stock. It’s affordable, stable in the right conditions, and gets the job done when your budget’s tight. Just know its limits, work within them, and it’ll serve its purpose.

Recommended Tools

If you end up working with MDF, here are a few things I actually use, and recommend.

Titebond Type I Wood Glue – still the best all-around adhesive I’ve found for wood-to-wood contact.

3/16” Brad Point Drill Bits – ideal for clean pre-drilling before attaching MDF to anything else.

Loctite PL Premium Adhesive – great for edge bonding and permanent joins when fasteners aren’t enough.

Dust Mask – don’t skip this. MDF dust is what I call “forever dust,” and it’ll get everywhere.

40-Tooth Saw Blade – perfect middle ground: sharp enough for clean cuts, not so fancy you’ll cry when MDF dulls it. This is a 10” blade for most table saws.

Track Saw - The track saw is by far the best and one of the safest ways to brake down sheet goods.

Some of the tools listed here are ones I personally use. When affiliate links are added later, they’ll help support this site at no extra cost to you.

My Ask

I’m not sponsored, and I don’t want to be. Everything you read here comes from my own experience, the good, the bad, and the occasional mistake. If you found this useful and want to help me keep building, you can “donate a nail” by using one of my links or chipping in a few bucks to support the site. Every bit helps keep this work going and lets me keep sharing what I’ve learned without having to answer to anyone but you.