Building a Solid White Oak Entry Door (Craftsman Style, Mortise & Tenon Construction)

The door in question…

This post is about installing a new entry door in my home.

I originally installed this door when we built the house. It was the cheapest entry door that met code requirements. Nothing wrong with it. It keeps weather out. It locks. It does its job.

But I installed it knowing full well I’d build a custom solid wood door down the road.

The entry door matters.

It’s the threshold into your personal space. It’s the first thing someone touches before stepping into your home. There’s an opportunity there — whether you use it or not — to show personality.

If I leave the builder-grade door, that says something. It says economical. It says landlord. It says, “good enough.”

I’d rather it say craftsman.

Quality.

Longevity.

So I’m building my own.

Some links in this post are affiliate links. As an Amazon Associate I earn from qualifying purchases. If you choose to buy through these links, I may earn a small commission at no extra cost to you. I only recommend tools I actually use.

The Design: Simple on Purpose

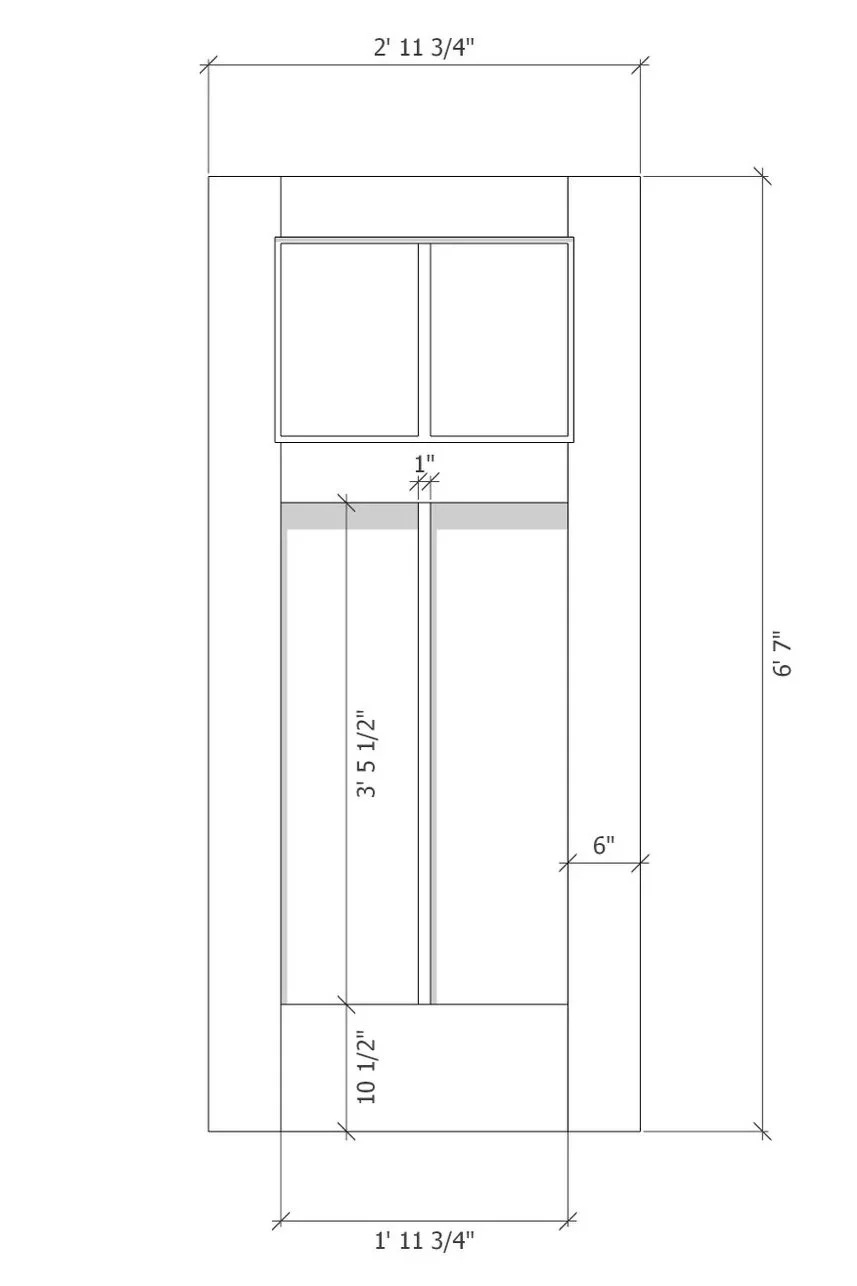

The door will be fairly simple:

36" entry

Two-panel layout

Top 1/3 glass

Bottom 2/3 solid white oak panel(I’ll cut the panel groove with a ½″ straight or groove router bit.)

Craftsman / Shaker style

Originally, I planned something more elaborate. But we’re moving. That changes things.

When you know you’re not staying forever, you simplify, not because you don’t care, but because you draw the line where it makes sense. I still want it to be beautiful. I still want it to last 150 years. I just don’t need to lose weeks of life carving flourishes no one asked for.

Character without excess. That’s the goal.

The glass section will likely be divided into two lights with a small oak mullion running vertically. Clean. Proportional. Nothing busy.

Why White Oak

I chose white oak for a few reasons.

First, durability.

White oak stands up to the elements. It’s stable. It’s tough. It resists splitting.

If you’ve ever split white oak firewood, you know what I mean. The fibers interlock. They fight you. Red oak, by comparison, splits straight and easy. A few good swings and it’s apart.

White oak doesn’t give up like that.

That interlocking grain also makes it more resistant to checking and splitting over time — important in a 36" exterior door that’s going to weigh a lot and live in the Arizona sun.

Second, rot resistance. White oak has natural resistance to moisture and decay. That matters on an exterior application.

Third, color.

Walnut would have been too dark. Mahogany too rich. The interior of my house leans off-white. White oak gives me that calm, yellow-tan tone that complements instead of competes.

It’s warm without being loud.

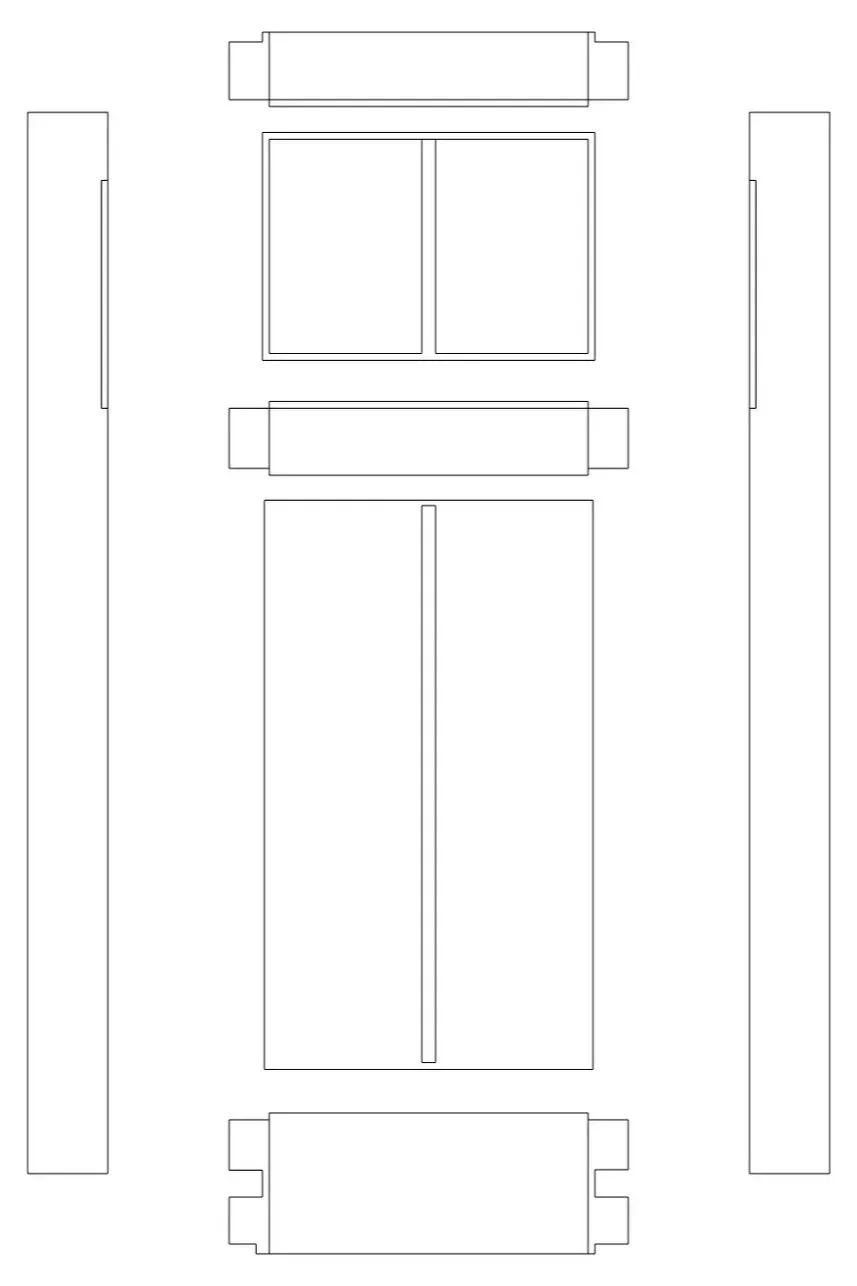

Exploded entry door- note the mortise and tenon construction

Construction: No Shortcuts

When I say solid wood, I mean solid wood.

Solid white oak. No veneer. No engineered core. Even the lower panel will be solid oak. The only non-oak element will be the glass.

Joinery will be traditional mortise and tenon.

Tenons roughly 3½" deep (find a good mortise chisel here)

Likely drawbored and pinned

Mechanical connection + glue

Traditionally, some builders would go full through-tenon. I won’t. Again, I’m selling the house. I’m not trying to prove something to a museum curator. I’m building something extremely solid, but I’m not going to get theatrical about it.

For a heavy 36" exterior door, mortise and tenon is the only real option I’d consider. Anything else is compromise.

Hardware

I’ll use square hinges.

As for the lockset, I may reuse the simple lever that’s currently installed.

It’s not glamorous, but it’s practical. You can open it with groceries in your hands. With a kid on your hip. With an elbow if you need to.

Sometimes simple is better than fancy.

Finishing Strategy

Minwax polycrylic ultra flat water based finish

Interior finish:

1–2 coats shellac sealer

Followed by water-based poly (flat or satin)

Water-based finishes(see previous post on finishing) are durable and stable, but they don’t add much depth. Shellac underneath adds warmth and tone without over complicating the system.

Exterior finish:

3–4 coats (likely 4) System three marine spar varnish SATIN

We get brutal UV exposure in the high desert. System three marine spar varnish SATIN holds up. It’s flexible. It has excellent UV resistance. If you’re going to build a white oak door, don’t sabotage it with weak exterior finish.

SketchUp Is Not Optional

Before I cut anything, I model it in SketchUp.

Every rail.

Every stile.

Exact dimensions.

Not because I can’t do the math — but because I don’t want to keep doing the math.

The model gives me:

Proportion preview

Cut list

Joinery measurements

Confidence

Once I’m in the shop, I want to build — not re-calculate.

The Cost (And Why It’s Worth It)

My local yard in Prescott wanted $17–18 per board foot for 8/4 white oak.

So I drove to Spellman’s in Phoenix.

They had it for around $11 per board foot.

I bought:

35 board feet of 8/4

12 board feet of 4/4

Total: $557

Estimated total material cost: $650–700

You can’t touch a solid white oak entry door for under $4,000 — and that’s conservative.

So yes, it’s time.

Yes, it’s labor.

But materially? It’s a bargain.

The only downside is I won’t get to take it with me when we move.

That’s life.

The Bottom Line

- 🔨 The Layout: Two-panel Shaker design. One-third glass with a simple oak mullion. Two-thirds solid white oak. Clean. Proportional. No fluff.

- 🔨 The Hardware: Stick with the lever lock. If your hands are full, beauty doesn’t matter. Function wins.

- 🔨 The Joinery: 3½" mortise and tenon, likely drawbored and pinned. Mechanical strength — not just glue.

- 🔨 The Money: Don’t pay $18 per board foot if you don’t have to. A two-hour drive saved a couple hundred dollars. Easy decision.

What’s Next

I’ll document this in stages:

Construction post

Installation + hardware

Finished photos

If you’re interested, subscribe to the email list so I can let you know when the next parts go live.

And if you’re curious what white oak looks like under finish, check out my post on water-based poly across different species. I’ve got sample shots there that will give you a good idea of how this door will look once it’s sealed up.

Tools Used In This Build

Narex ½″ Mortise Chisel (solid steel at a great price) – https://amzn.to/4rrrUWe

½″ Groove Router straight Bit – https://amzn.to/3ZEeREH

System three marine spar varnish SATIN – https://amzn.to/4tIzuNw